Plasma Enhanced Chemical Vapor Deposition (PECVD) system for coatings from the gas phase with activation of working gases by induction discharge plasma (ICP)

Features:

Excellent adhesion of the coatings

Higher deposition rate in comparison with PVD methods

Low temperature processes without decreasing film parameters

Films conformity

Possibility to make coatings on the substrates of complicated shapes with high level of uniformity

Fully automatic system of ICP impedance matching

Bigger maintenance intervals (self-cleaning function)

A wide range of options which help to increase vacuum system capabilities and implement variety of tasks with ICP CVD method of deposition

Additional options:

Load-lock vacuum chamber with the mechanism of automatic substrates loading to the technological vacuum chamber

Scrubber for the exhaust cleaning

Gas cabinets for the toxic, flammable and explosive gases

Thermostat

Systems of heating the walls of technological vacuum chamber and pipes

Additional external pumping circuit for achieving an extremely clean deposition process

Additional gas lines

Nitrogen (N2) chamber filling system

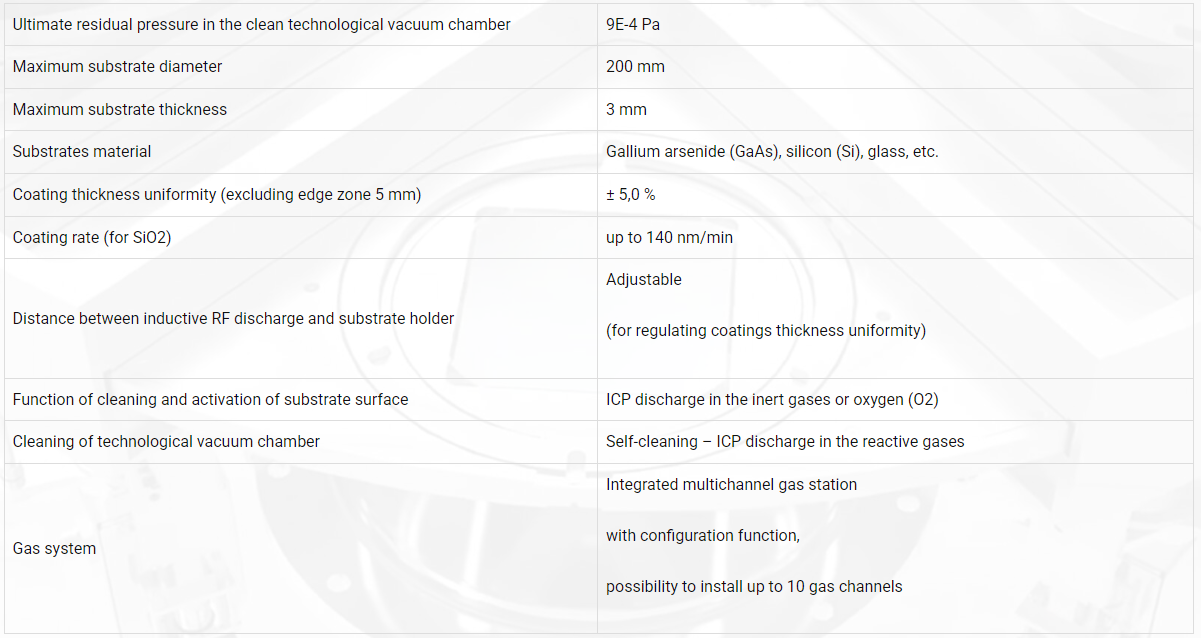

Technical data:

Additional features:

Liquid reactive chemicals supplying System

Electrostatic clamping of the substrate

Substrate holder design with RF bias, which allows the energy spectrum of the plasma to be adjusted.

Optical emission spectroscopy

Integration into clean room

Substrate thermal stabilization system with helium (He) supply under the bottom of the substrate