Vacuum system for optical coatings with magnetron sputtering and RF plasma oxidation technology (Meta mode)

The technological method represents the deposition of thin layers of metals (1-3 nm) or semiconducting materials with the following oxidation of the layer in the ionized gases environment. The method allows to receive high quality dielectric coatings with the high deposition rate. Vacuum system configuration allows to deposit two different materials in one technological process with controllable deposition rate for each material.

RF plasma source as well intended for cleaning and activation of the substrates surfaces before deposition process.

Drum type substrate holder, load-lock vacuum chamber, single wave or broadband monitoring system allows to reach high productivity of the system with the high yield.

Technological devices:

RF plasma source

Two DC-magnetrons

Features:

High deposition rate

Load-lock vacuum chamber

Substrate holder of drum type with the set of faces of different sizes

Single wave or broadband optical monitoring system

Simultaneous deposition of two different materials with controllable deposition rate for each material

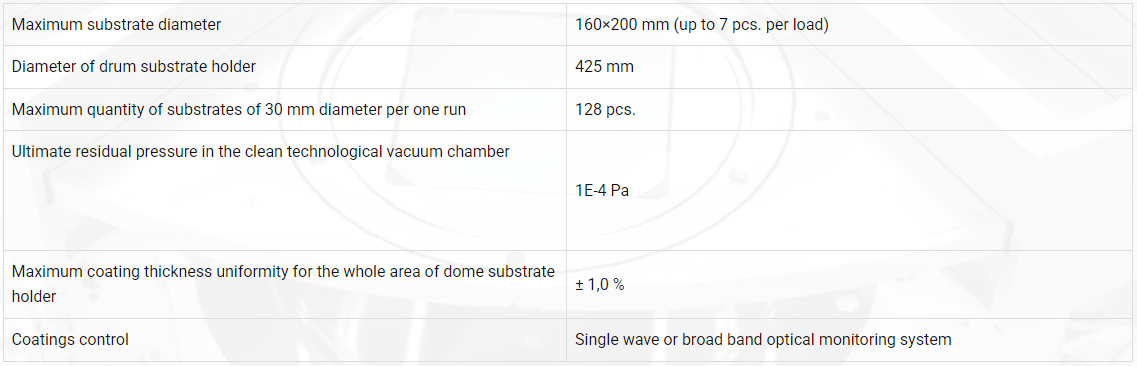

Technical data: