Vacuum system that combines E-beam evaporation and magnetron sputtering technologies in one vacuum cycle

Features:

Magnetron and electron beam deposition of thin films on two sides of the substrate in a single manufacturing process

Fully automated optical monitoring system in the wavelength ranges from UV to mid-IR (E-beam module)

Quartz control system (magnetron module and E-Beam module)

Possibility to integrate the equipment into a clean room

The equipment includes three modules:

E-beam technological module – designed for coating by electron beam evaporation with simultaneous ion assist on one side of the substrate.

Magnetron process module – designed for coating by magnetron sputtering of the target with RF pre-cleaning on the second side of the substrate.

Loading module – provides manual installation of substrates on the substrate holder and automatic movement of the substrate holder into the process modules without venting the process chambers.

The coating is applied to the substrates fixed on the disc substrate holder. Full automation of the processes of ion cleaning and assisting, evaporation and sputtering, using of quartz thickness monitor and optical control allows to obtain coatings with required properties and guaranteed repeatability.

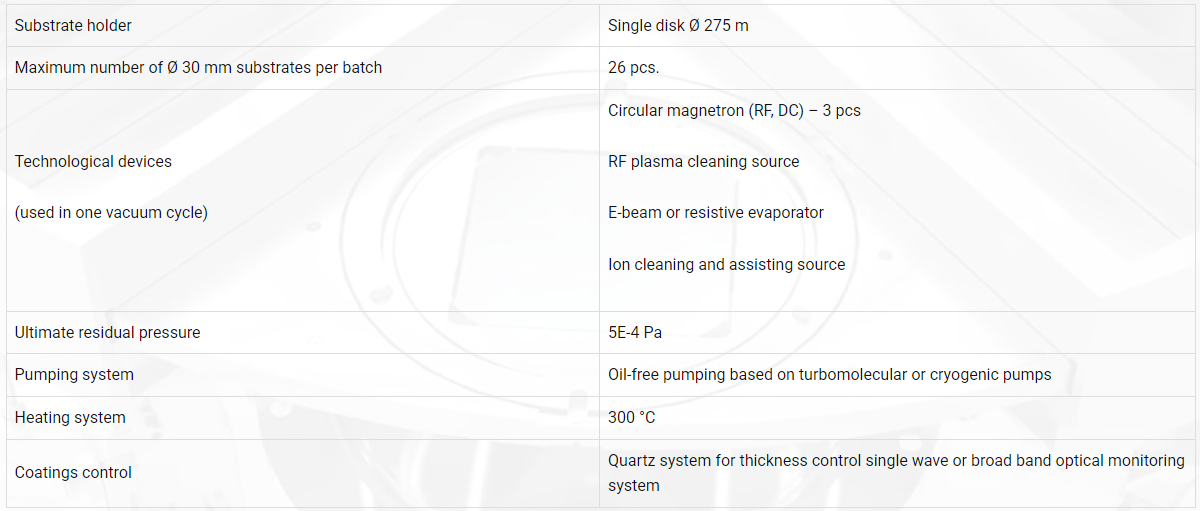

Technical data:

Technological devices:

DC- magnetrons

RF-magnetrons

E-beam

Resistive evaporator

RF ion source

Ion beam cleaning source