Magnetron sputtering is a technology for thin films depositing in a vacuum chamber and in a working gas using cathode sputtering of the target material in crossed electric and magnetic fields.

Electrically conductive materials, such as conductors and semiconductors, are used as targets in medium-frequency DC and AC magnetrons. The use of magnetic materials is limited by the thickness of the target and requires the use of a special magnetic system. For the sputtering of dielectric materials, the RF version of the magnetron is used, which also requires a RF-generator and a matching network for the applied discharge system.

Application:

Round magnetrons are used in vacuum laboratory and batch equipment with substrate sizes up to 250 mm.

Main tasks:

– production of optical, semiconductor devices, thin-film hybrid integrated circuits, piezoelectric products, acoustoelectronics;

– deposition of functional coatings: optical, conductive, protective, dielectric, metallization of the surface of plastic and glass products, etc.

Planar round magnetrons are used in Elato, Atis, Smart, Izolab.

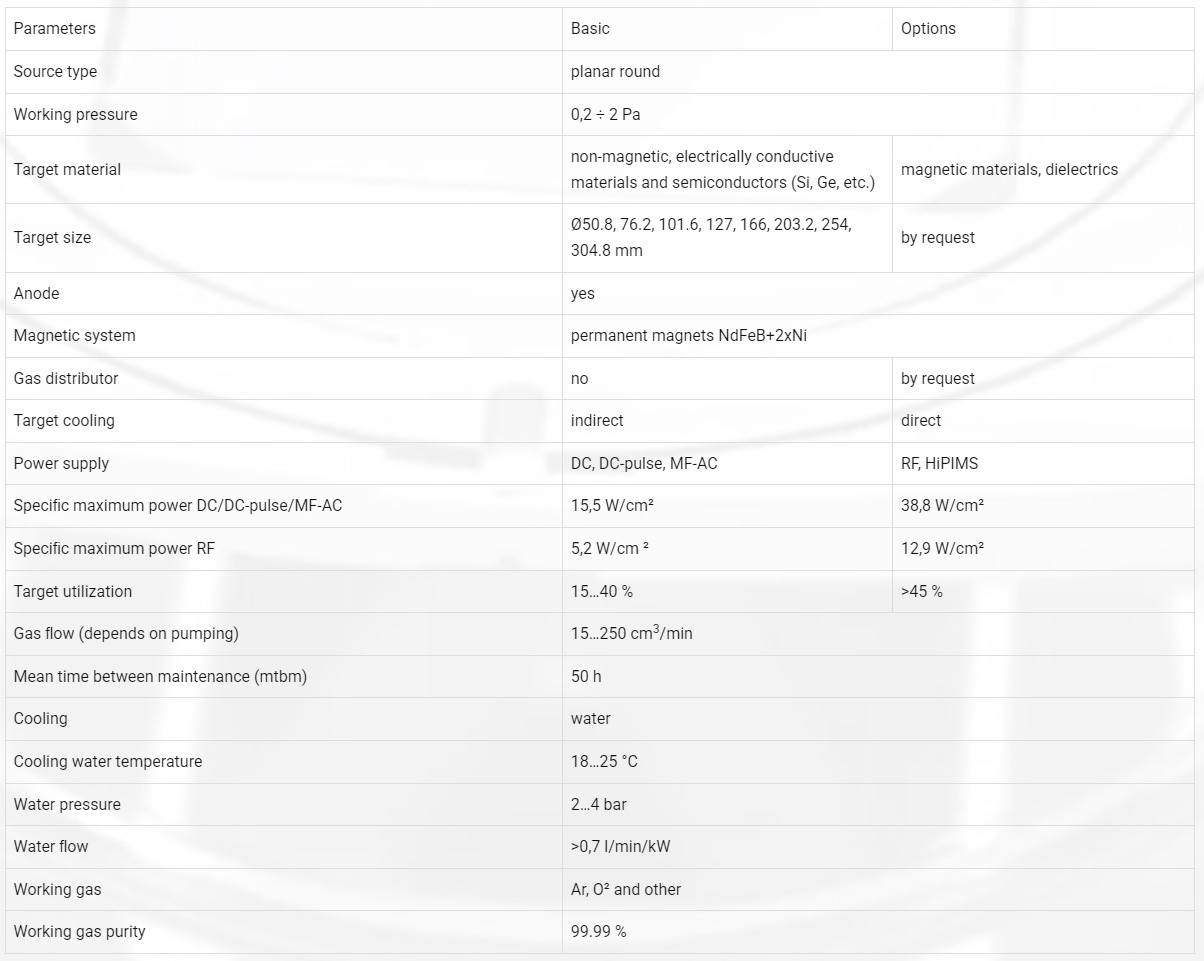

Technical data: