Magnetron sputtering is a technology for thin films depositing in a vacuum chamber and in a working gas using cathode sputtering of the target material in crossed electric and magnetic fields.

Electrically conductive materials, such as conductors and semiconductors, are used as targets in medium-frequency DC and AC magnetrons. The use of magnetic materials is limited by the thickness of the target and requires the use of a special magnetic system. For the sputtering of dielectric materials, the RF version of the magnetron is used, which also requires a RF-generator and a matching network for the applied discharge system.

Application:

Cylindrical rotary magnetrons are used in a vacuum equipment of periodic and continuous operation with substrate sizes up to 3 meters or more. Such magnetrons are especially in demand in vacuum equipment for serial and mass production, where there are important such parameters as target lifetime and long-term stability of coating processes.

Main tasks:

– deposition of functional coatings in the production of displays, the production of energy-saving, electrochromic architectural glasses, solar cells, etc.;

– deposition of functional coatings: optical, conductive, protective, dielectric, metallization of the surface of plastic and glass products, etc.

Cylindrical rotary target magnetrons are used in Versus-74, Aurora.

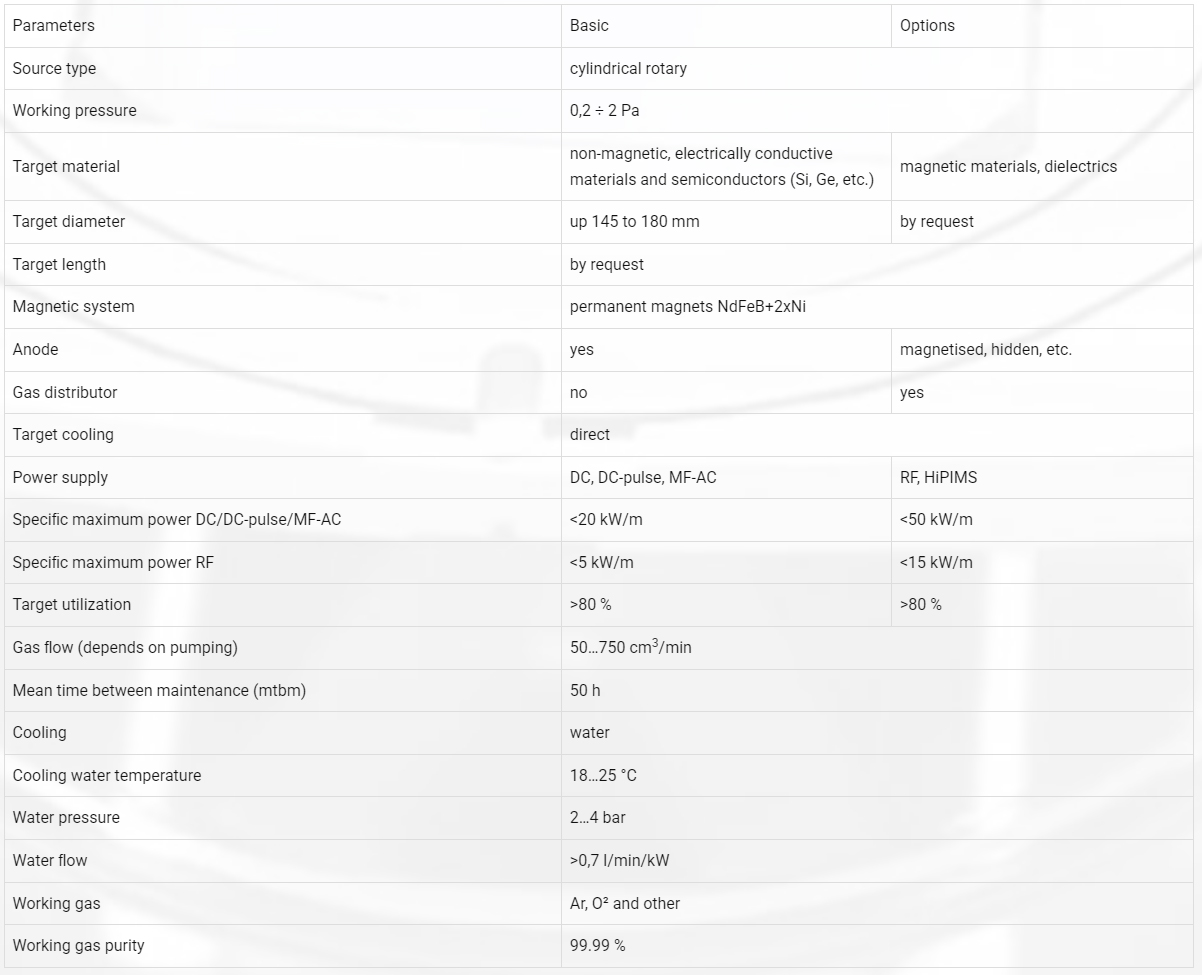

Technical data: